Baking II

We continue with some basic concepts in bread baking. If you want to see the first part of this entry, you can find it here.

Crust

Upon placing the dough in the oven, the outer part rapidly increases in temperature, being in contact with areas (floor or air) that are at a temperature close to 200°C. When this zone reaches 100°C, heat is invested in evaporating the water present, halting the temperature rise. At this point, as water evaporates, part of the interior moisture exits towards the external parts to equalize the humidity inside the pieces. If this process occurred at very low temperatures, close to 100°C, this transition would be constant, drying the entire piece without significant differences between the interior and exterior. However, in bread baking, the evaporation of water from the outer part is faster than the arrival of moisture from the interior to the exterior. The consequence is the formation of a drier crust on the external surface. Once the crust is formed, the passage of moisture from the interior to the exterior is minimized, and the temperature of this zone continues to rise until reaching a point where Maillard reactions and sugar caramelization begin, responsible for the final colour of the pieces.

Maillard reactions, although starting at much lower temperatures, usually become visible around 130°C approximately. These reactions, simplifying a lot, occur between amino acids (components of proteins) and reducing sugars. Monosaccharides (such as glucose or fructose) and disaccharides (such as sucrose or maltose) have a higher reactivity than other more complex sugars. In the dough, we usually have maltose and, to a much lesser extent, glucose, both generated by the hydrolysis of starch by the action of amylases. Sucrose or other sugars may also be present if added. As wheat flour also contains proteins, a source of amino acids, all the ingredients are present for these reactions to occur, generating compounds with brown hues. The colours generated depend on the type of amino acid, type of sugar, and pH of the medium, among other factors. Lactose, typical in dough with added milk, tends to have reddish tones. Alkaline pH dough, like pretzels, exhibits very different, brighter colours. These reactions are responsible for the formation of acrylamide, which will be discussed in another entry.

Sugar caramelization reactions occur at different temperatures depending on the type of sugar and the conditions of the medium. But for sugars present in bread dough, this occurs between 160 and 180°C. As commonly known, sugars tend to darken and acquire shades between brown and black when caramelized.

The combination of Maillard reactions and caramelization generates the final colour of the crust. These reactions also contribute to the typical flavour and aroma of the crust. The colour of the exterior of the bread during baking usually marks its completion. If baking is prolonged more than necessary, the bread takes on darker tones, which are also associated with more bitter flavours and a higher content of acrylamide, both undesirable.

Crumb

Unlike the external part of the pieces, the heating inside is slower, and it will be somewhat slower in the central part since the heat must penetrate. As the temperature increases, like in most materials, the viscosity and consistency of the dough slightly decrease, which may facilitate expansion. But if the dough lacks minimal consistency, it can collapse or flatten. When the gelatinization temperature is reached, starch swells and breaks, forming a more or less homogeneous mass, increasing the viscosity of the medium, creating more rigid and less flexible structures. From this moment, the dough cannot expand further, and the increase in the volume of the pieces during baking stops. However, processes that increase pressure to expand the pieces may still exist. If this happens, the pieces tend to break irregularly, usually on one side. For this reason, cuts are made on some types of bread before baking so that they break or open along those pre-cuts, creating a more appealing final shape. The gelatinization temperature depends on the type of flour (each starch has a different gelatinization temperature) and the conditions of the medium, but generally, in wheat bread, it is around 70°C.

After gelatinization, we can stop baking and refrigerate or freeze the dough. Since the dough is more rigid, it can be handled, and baking can be completed later. Before gelatinization, the dough is very soft and impossible to handle without breaking. It is essential to note that, as the baking process is not completed, the dough has higher moisture content, posing a higher risk of microbial spoilage. For this reason, it is more common to freeze this type of dough.

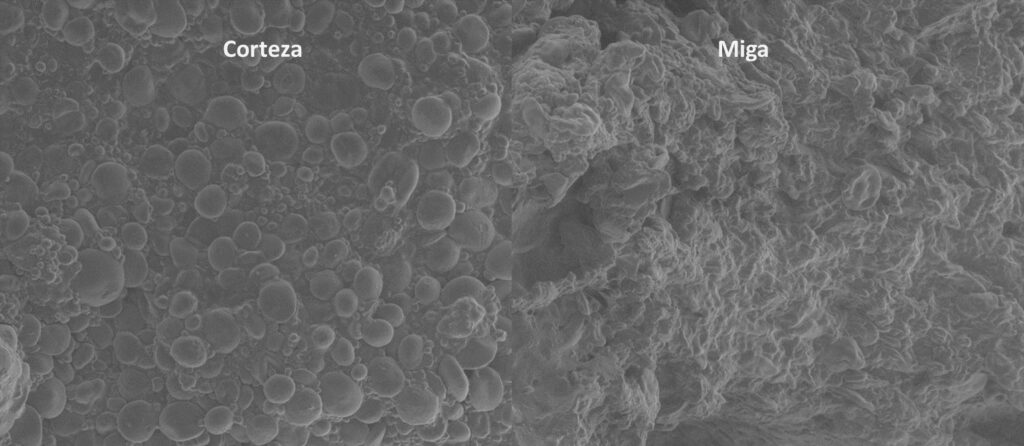

It should be highlighted that for starch gelatinization to occur, heat and moisture are necessary. This is why this phenomenon hardly occurs in the crust. Although the starch gelatinization temperature is reached, it quickly rises, evaporating the water present in this area of the pieces, preventing further gelatinization. Thus, electron microscope images show a crumb structure with completely broken starch granules, while in the crust, starch granules that have not broken can still be distinguished.

Crust and crumb of bread viewed under an electron microscope.

Steam in Baking

A common practice involves injecting steam at the beginning of baking. It is important to consider that the pieces are introduced into the oven at the fermentation temperature (between 20 and 40°C in most cases). If there is steam in the oven, it cools upon contact with the pieces and condenses on them, forming a very fine water film. This water film will reheat with the oven’s heat and evaporate when the water’s evaporation temperature (100°C) is reached. Therefore, all heating phenomena of the pieces will be slightly delayed, and, being somewhat more humid, the outer parts of the pieces will be somewhat more flexible in these early stages.

The result of injecting steam in baking usually leads to thinner crusts with a shinier colour. This process also slightly affects the expansion of the cuts in the pieces. It seems to increase the volume of the bread slightly by improving expansion, although this effect is not as evident. If no steam is applied, the pieces typically generate thicker crusts with a more matte colour. Therefore, the application of steam depends on the results you want to achieve.

Oven Draft

Ovens usually have the ability to open or close ducts through which gases formed during baking can escape. This is often called the oven draft, and it can be left open or closed. Water vapor usually accumulates inside the oven, generated from the moisture in the pieces. When water vapor concentrates around the pieces and saturates the atmosphere surrounding them, the continuity of this process is hindered. To facilitate it, ventilation is usually employed. That’s why many ovens have fans that remove the water vapor formed from around the pieces. An open draft can facilitate the release of this water vapor. In a completely airtight oven (bakery ovens are not airtight), pressure inside can increase significantly as baking progresses, hindering the expansion of the pieces. In this case, it would be advisable to open the draft to release that pressure and facilitate expansion. But, as mentioned, this effect is not as evident. It should also be considered that if the oven draft is opened, heat escapes, making it more challenging to maintain a high temperature, and the energy cost may be higher. Ultimately, we must think that the position of the oven draft will affect our results, and we must study in each case what is more convenient.

Temperature Ramps

Although in most small bakery ovens, we can only set one baking temperature, in many industrial ovens, it is possible to modify the temperature at each phase of baking. We can even modify the position of the draft or other factors in each phase. Baking can be divided into three main phases. In the first phase, the pieces expand. In this phase, enzymes and yeast are still active, starch has not gelatinized, and the crust has not started to form. In this phase, it may be interesting to reduce the oven temperature to enhance this effect (lengthen this phase). In the central phase of baking, the outer part of the pieces has reached 100°C, and the crust begins to form, and the central part has reached the gelatinization temperature, and the piece becomes rigid. It may be interesting to slightly raise the temperature if we want to accelerate these processes. In the last part of baking, the outer part of the pieces reaches the appropriate temperature for Maillard reactions and sugar caramelization, the crust turns brown, and the typical aromas of bread baking develop. In this phase, it may be interesting to slightly reduce the temperature to enhance these effects without the risk of the bread “burning”. However, for each preparation and depending on the desired outcome, it may be interesting to modify temperatures in some other way. The important thing is to know that if we have an oven with these characteristics, we can play with these parameters and not limit ourselves to a single baking temperature.

The topic of baking is complex, and there are still some aspects that have not been covered in this entry, such as baking other products or types of ovens. We will address these topics in future entries.