Equipment for Quality Control I: Kneading

We have previously discussed flour quality control in this blog and the importance of gluten in certain applications (although not all). However, in flour quality control, there are specific pieces of equipment that simulate certain parts of the processes and analyse how flours behave in them. Some equipment is more closely related to kneading, while others are focused on shaping or handling dough, fermentation, or baking. In this entry, we will focus on equipment primarily used for kneading.

What Happens During Kneading?

During the initial phase of kneading, the ingredients are mixed, and specifically, the protein in wheat flour hydrates. Subsequently, the mechanical work provided allows the development of the gluten network. If kneading continues, this gluten network can weaken, which is detrimental to the breadmaking process. All these changes affect the rheology of the dough and can be monitored with specific equipment. Among these devices, the farinograph stands out due to its age, the extensive body of literature available on it, and the reliability of the manufacturer, which has continued to improve and update it over time. That’s why we will discuss the farinograph, followed by other interesting equipment.

Farinograph

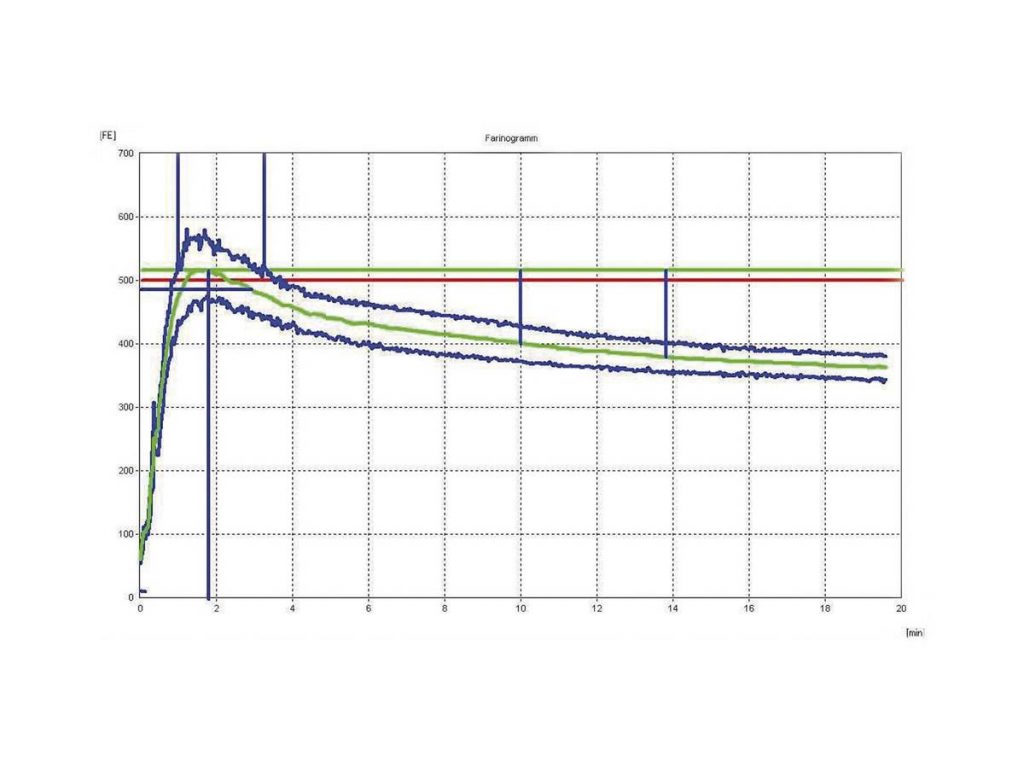

The farinograph consists of a kneading machine capable of measuring the force required by the kneading paddles to move the dough. Therefore, it functions as a continuous rheometer. To conduct the analysis, a quantity of flour must be added to the kneading machine. The analysis begins with the addition of water and the control of the dough’s consistency. This consistency reaches a maximum after a certain time, after which it begins to decrease or at least remains stable. The official method states that the moisture content of the test should be adjusted to center the maximum consistency at 500 Brabender Units (BU). This is hardly achieved in the first attempt, so the test may need to be repeated one or two times until the adjustment is successful. If the consistency of the first test is very high, you should increase the amount of water. Conversely, if the maximum consistency is lower than 500 BU, you should reduce the amount of water. Once a maximum consistency of 500 BU is achieved, the analysis continues for 20 minutes.

The first value provided by the farinograph is the amount of water required to reach 500 BU, which is called flour absorption. This value is related to the composition of the flour and tends to be higher when the protein percentage increases, when there is more damaged starch, or when there are more arabinoxylans, for example. However, it is not related to gluten quality. Another value obtained from the equipment is the dough development time, which is related to the optimal kneading time. This value is often associated with protein quality, with stronger flours typically requiring longer kneading times. The farinograph also provides several values related to the rate at which the dough loses consistency after reaching its maximum, such as dough stability or decay. These values are also related to gluten quality, and stronger flours tend to withstand over-kneading better. Due to the relationships between farinograph parameters and gluten quality, in certain countries, the farinograph analysis is one of the most commonly used methods to evaluate the baking quality of flours.

It’s important to note that dough development in the farinograph typically takes between one and four minutes. Therefore, it is a fast kneading process compared to many kneading machines commonly used in Spanish bakeries, especially those with arm or fork kneaders. This is one of the reasons why the farinograph has not gained widespread use in some countries, like Spain. However, the adoption of faster kneading methods, such as spiral kneaders, and particularly some intensive industrial kneading systems capable of kneading in less than a minute, make gluten quality even more critical. Consequently, farinograph analysis is becoming more important and provides additional information compared to the alveograph.

Up to this point, we have discussed the farinograph as a flour analysis tool. However, one of the significant advantages of the farinograph is its potential for research and development (R&D) because it serves as an excellent kneading machine. With this equipment, we can analyze how kneading changes with any formulation modification, work with different consistencies, and even work with the same dough used in the production process. Additionally, we can adjust dough temperatures and other parameters. Moreover, we have more than one kneading machine since Brabender offers various accessories to change the kneading machine, allowing us to work with different sizes and kneading devices.

In summary, the farinograph is a highly valuable piece of equipment for both flour analysis and R&D purposes. However, the major drawback of the farinograph is its cost, which is typically higher than that of similar equipment.

You can find more information about the farinograph on the Brabender website.

Similar Equipment to the Farinograph

Over time, various more or less successful copies of the farinograph have emerged. There used to be an Austrian company, and currently, there are Turkish and Chinese replicas. While the costs are much lower, and the basic functionality is similar, they do not offer the same level of technical support, equipment reliability, or possibilities.

However, among the equipment similar to the farinograph, I believe the DoughLab, from Perten (now part of PerkinElmer), deserves special mention. When this equipment was introduced, it improved certain aspects of the farinograph, such as ease of assembly and disassembly of the kneading bowl, as well as the ability to modify test conditions and data handling. Furthermore, it is backed by a highly reputable company with excellent technical support. The entry of this equipment into the market has led to significant improvements in recent versions of the Brabender farinograph, and the price difference is not as significant as with other lesser-known brands.

For more information about the DoughLab, you can refer to the PerkinElmer website.

Equipment with Extra Features

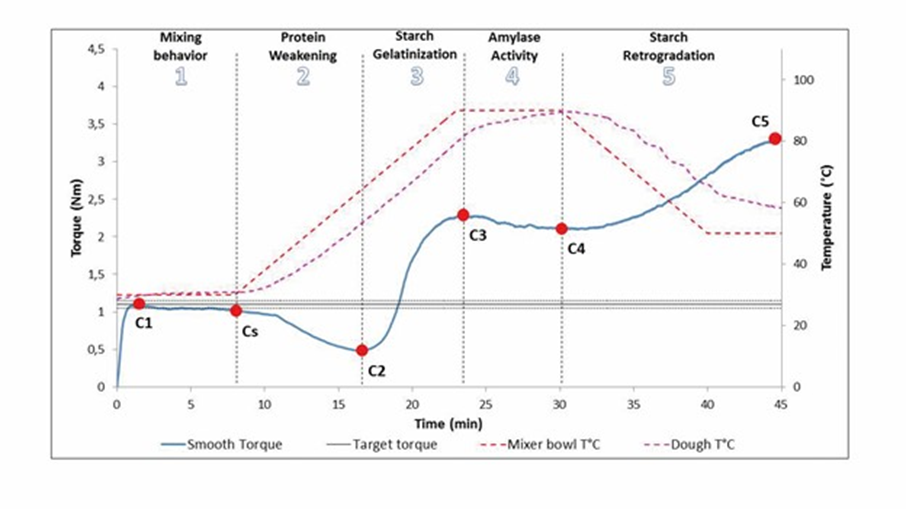

Among the equipment that also analyzes flour behavior during kneading, the Mixolab must be highlighted. This equipment operates similarly to the farinograph in its initial phase, with the difference that the kneading machine is much smaller. This has the advantage of requiring less flour for analysis, which is particularly useful in genetic improvement programs where only a few samples are available or when reagents are expensive. For these tests, Brabender offers a smaller kneading machine than the standard one but not as small as the Mixolab’s. The downside of having a smaller kneading machine is that it cannot be used for breadmaking trials.

The main advantage of the Mixolab is that, after the kneading phase, it subjects the dough to heating and cooling, similar to what the RVA or viscoamylograph does, but with a flour/water ratio more similar to that in baking. This information may be related to the dough’s ability to expand in the oven or the final texture of the bread. However, more research is needed to make certain claims about this equipment. It has been used in studies to examine the effect of certain ingredient changes, but further research is required to correlate these analyses with product characteristics.

Therefore, the Mixolab provides information similar to the farinograph but also provides additional information. However, research is needed to determine the practical utility of this additional information. Additionally, it cannot be used for breadmaking trials, and it lacks the versatility of the farinograph in terms of changing kneading machines.

For more information about the Mixolab, you can visit the Chopin website.

And on a Larger Scale?

While they are not designed as quality control equipment, there are also kneading machines with dough behavior analysis systems. These kneading machines work similarly to a farinograph but do not have the precision or repeatability of the farinograph. Nevertheless, they are very useful for R&D pilot plants because they allow for breadmaking with much more controlled dough than standard kneading machines, enabling the study of the effects of formulation changes during kneading. Perhaps the most well-known ones are from the Diosna brand, but there are other more affordable brands that offer similar equipment.