Quality Control Equipment II. Handling

Among the equipment for quality control of dough and flour, those that mimic dough handling, along with those that simulate kneading, are some of the most commonly used. Among these, two stand out: the alveograph and the extensograph.

Alveograph

Undoubtedly, the alveograph reigns as the king of flour quality control equipment in Spain and some other Mediterranean cultures. However, in English-speaking countries, the farinograph or other devices are more common. The alveograph is a device produced by the French company Chopin, which has undergone modifications and improvements over the past few decades. Its adoption in Spain occurred in the second half of the 20th century, and the companies that marketed it successfully made it the fundamental equipment for flour quality control, establishing a common language in the Spanish wheat industry. Therefore, its use is indispensable in flour mills today if you want to communicate effectively within the industry. This is the great advantage of the alveograph, but it has several disadvantages that we will discuss later.

The alveograph includes a small kneading device where flour is mixed with water, and the gluten network is developed. The amount of water is adjusted based on the flour’s moisture content to achieve a consistent final moisture level. Some professionals have criticized this aspect, suggesting that it would be preferable to perform the analysis at a constant consistency rather than constant hydration. This modification may be useful for very strong flours that yield more consistent dough with the same hydration. However, in Spain, the language used is based on traditional analysis at a constant moisture level. To perform the analysis at a constant consistency, Chopin introduced the consistograph, a device that analysed how the flour behaved during kneading and allowed you to adjust the moisture to achieve a consistent consistency. However, it has not gained widespread use and has not replaced the farinograph. Another option for performing the analysis at a constant consistency is to have a farinograph and use the farinographic absorption or a modification thereof for the analysis.

Classic Alveograph

After kneading, the dough is sheeted and circular portions are cut, following a well-defined method. These portions must undergo a resting period in a chamber under fixed temperature and humidity conditions. After this resting period, the analysis is performed. The edges of the circular pieces are held, and air is blown into the centre. This process results in the formation of a bubble because gluten can expand and retain air. The equipment records the pressure inside this bubble until it bursts, at which point the test ends. In general, five pieces of dough are obtained from the same dough, resulting in five curves, from which an average is calculated.

The obtained curve provides several useful parameters. The surface inside the curve indicates the flour’s strength (W) and is the most commonly used parameter in Spain for buying and selling wheat and flour. The height of the curve indicates dough tenacity (P), or how resistant the dough is to deformation. The length of the curve is called extensibility (L), indicating how much the dough can be stretched before breaking. Although both parameters can be considered separately, it is common to refer to the relationship between tenacity and extensibility (P/L), known as flour balance. Different types of products require varying strengths (W) and balances (P/L). Products that require weak gluten and highly extensible dough, such as Maria-type biscuits, demand flours with low strength and a very low balance. As products require stronger gluten, there is a greater need for higher strength (W) flours. For instance, bread dough that includes ingredients reducing gluten strength, like sugar, fats, or bran, often requires stronger flours. Additionally, the more mechanized the process, the less desirable flours with high P/L values tend to be. Extensibility is also important when doughs need to undergo sheeting processes, such as puff pastry or pizza dough.

Alveogram

It is important to note that this analysis is based on the formation and quality of the gluten network. In fact, it cannot be performed with gluten-free flours as the bubble formation does not occur. Therefore, it is not useful for evaluating flours in processes where gluten does not form, as discussed in previous entries, such as many types of cookies, batter doughs, or scalded doughs.

In addition to W, P, and L, there is another parameter called Ie (elasticity index), which indicates how the curve decreases after reaching its maximum (P), as it can decrease more sharply or gradually. This parameter is not commonly used but may be a better predictor of flour suitability for certain applications than the more frequently used parameters.

For more detailed information on the alveograph, it is recommended to visit the Chopin company’s website, which provides extensive documentation with explanatory photographs and graphics.

One of the advantages of the alveograph, besides serving as the most widely used language for flour quality in Spain, is its ability to perform analyses at different times thanks to its resting chamber. By comparing the initial analysis with one conducted after a longer resting time, possible enzymatic activity that gradually modifies the dough can be detected. This has been used to detect the presence of cereal bugs (garrapatillo) attack. These insects inject a complex enzyme into the grain with a high load of proteases, which can degrade the gluten network during baking processes, severely impacting bread quality. If grains have been attacked by these insects, the alveographic curves lose strength and extensibility over time. Typically, the initial analysis is compared to the one conducted after two hours to obtain a parameter called degradation (percentage loss of W value). To confirm the presence of “garrapatillo” damage, both W and L values need to decrease.

However, the alveograph also has significant disadvantages. Firstly, its results are highly influenced by the person conducting the analysis, environmental conditions, and minor changes in its components (e.g., wear over time). This necessitates participation in intercalibration programs, which will be discussed in future blog entries, to ensure results are consistent with those obtained on similar equipment. While the latest versions of the alveograph have reduced this variability since bubbles are generated automatically within a closed atmosphere, it has not been entirely eliminated.

Modern version of the Alveograph

Another drawback is that the alveograph is not a very versatile device. It is not possible to change dough conditions (hydration, inclusion of other ingredients, etc.) and obtain results. For example, it cannot be used to analyse whole wheat flour unless it is re-milled. While the equipment has improved in this regard, from early versions where the curve had to be manually drawn and data collected afterward to current models where results can be stored and calculations are performed automatically, its flexibility to change formulations is limited. If the dough does not have a certain consistency, it is not always possible to obtain adequate bubbles and the corresponding curves.

Lastly, it should be noted that alveographic values are not magic and cannot, by themselves, guarantee the suitability of a flour for most applications. They provide helpful information, as do other gluten or flour quality values, but must be combined with others, such as farinographic values or protein content, for a comprehensive assessment.

Extensograph

This equipment is very interesting but relatively unknown in Spain. Additionally, it essentially serves as a small bakery because it includes a mini rounder, a mini molder, and a mini fermentation chamber. However, it requires a mini kneader, which the farinograph provides. The acquisition cost of both devices, if not already owned, is a significant drawback.

Extensograph

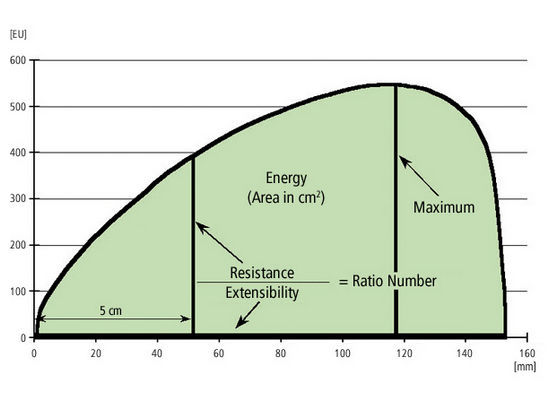

The dough from the farinograph must be manually divided and undergoes rounding, shaping (to form dough cylinders), and resting. The cylinders, placed in special devices, are deformed by a hook in the centre, and the dough’s resistance to deformation is recorded. A curve is obtained from which data similar to those of the alveograph are extracted, such as the area under the curve, maximum height, and curve length. The interpretation of these results is similar to that of alveograph data, and analyses can also be performed with different resting times. The main difference from the alveograph is that in this case, it involves uniaxial deformation (in one direction or axis), whereas the alveograph, by generating a bubble, analyses biaxial deformation. Intuitively, the deformation in the extensograph is more similar to dough handling during processing, while that in the alveograph resembles what occurs within the dough during fermentation.

Extensogram

The problem with the extensograph for flour analysis is that it is seldom used in Spain and, therefore, not well-known. Consequently, the parameters obtained are not very useful for buying and selling operations. Moreover, its results are not magical, and a comprehensive assessment that helps predict flour suitability in different processes can be achieved by combining it with other already used methods. Additionally, the high cost of acquisition, along with a farinograph (if not already available), is a significant drawback.

The great advantage of the extensograph compared to the alveograph is its versatility and the ability to work with dough under different kneading conditions, including dough from production lines or with significant changes in formulations. This, combined with the presence of small rounders and molders, makes it very interesting for R&D activities or for evaluating the effects of ingredient, additive, or enzyme changes.

For more information on the extensograph, you can refer to Brabender website.