Starch in baking

After discussing the role of gluten, it’s time to talk about the role of starch, which is the main component of flour, in the baking process. Although in the world of wheat flour and its quality control, a lot of importance is usually given to its proteins, starch performs basic functions in the bread-baking process that we should be aware of. In other processes or products, its importance is even greater, as the gluten network is not formed. Similarly, in the case of products made with gluten-free flours, starch often plays a fundamental role.

Damaged Starch

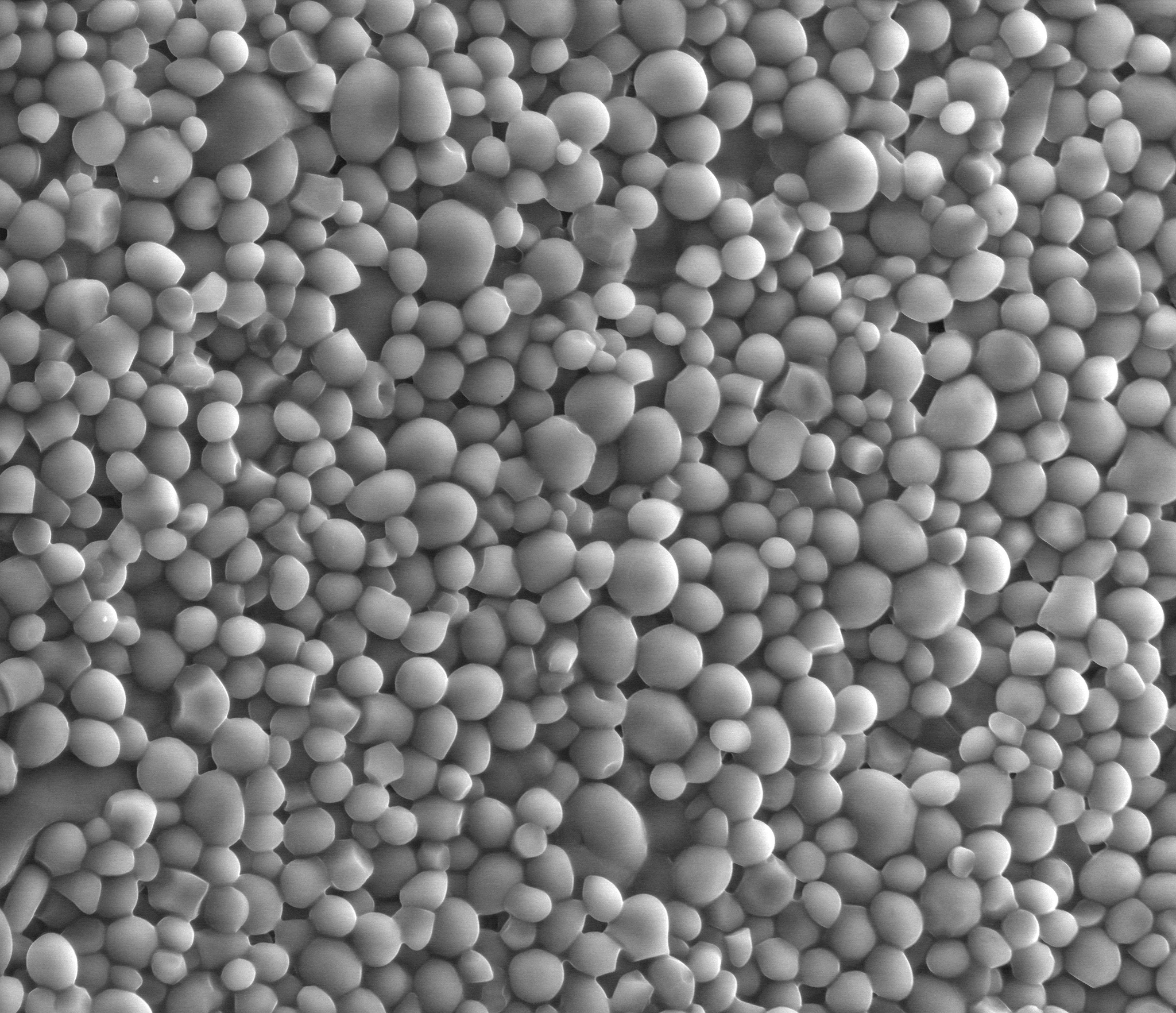

The first thing we should know is that starch is found in nature in the form of granules. These granules can be larger or smaller, and their shape can be polyhedral, rounded, or lenticular. The shape and size of these granules vary for each cereal. Specifically, in the case of wheat, there are two types of granules, both lenticular, with two different sizes. These granules are usually surrounded by a protein matrix that protects them. In general, starch granules are not degraded by the enzymes present in the dough, or they are degraded very slowly, so their action is not noticeable in conventional baking. However, during the milling process, some of the granules are damaged and can be attacked by enzymes later. This fact plays a fundamental role in the baking process because it is responsible for generating fermentable sugars that will feed the yeast during fermentation. The amount of damaged starch is slightly higher in harder grains and lower in softer ones. It is also higher in more aggressive milling systems and when trying to achieve finer particle sizes. Another important aspect of damaged starch is that it has a higher water absorption capacity than undamaged starch, so the higher the percentage of damaged starch, higher the cold thickening power of the flour tends to be, although other factors also influence it. Therefore, dough made with flours with high percentages of damaged starch may seem to require more water, but they tend to be stickier.

A high level of damaged starch will help generate an excessive number of sugars in the bread-baking process and can result in darker bread, as these sugars are not consumed during fermentation and participate in Maillard reactions, responsible for the crust colour. Conversely, a low content of damaged starch can lead to dough that cannot ferment, because yeast requires fermentable sugars to fulfil its role. In the case of wheat flours, the level of damaged starch usually ranges between 3% and 8% of the total starch present. This level is generally suitable for bread-baking processes. However, in the case of gluten-free bread, corn starch is often used as a source of starch. The level of damaged starch in these products is very low, so not enough sugars are generated in the bread-baking process. This is one of the reasons why sugar is often added to these formulations.

Amylose and Amylopectin

Starch is composed of amylose and amylopectin. Both substances are made up of glucose units, but while amylose is a linear chain, amylopectin is a much larger and branched molecule. Functionally, the important thing is that amylose tends to retrograde (see next point), whereas amylopectin does not, or at least not rapidly. Most cereals have an amylose content of around 25%, while amylopectin usually represents about 75%. Different varieties may have different amylose and amylopectin contents, and there are even varieties without amylose (waxy) or with a high amylose content. The number and length of branches also influence these properties, but this is more difficult to modify.

In the case of wheat, there are waxy varieties that have been proposed for use in baking to reduce bread hardening, but they have not been successful for this purpose. Perhaps, in part, because the quantity and quality of proteins are more important in the baking process, and the variety of waxy wheats is still limited. It should also be considered that, as will be seen, these varieties will affect the texture and appearance of the crumb.

Gelatinization and Retrogradation

Perhaps the most important aspect of starches is their behaviour when heated and then cooled. When starch is mixed with water and heated, the granules begin to swell, and the consistency of the paste increases significantly. This phenomenon is observed when making a béchamel sauce, for example, and is known as gelatinization. The gelatinization of starch occurs at a temperature, usually between 60-70°C (140-158°F), depending on the type of grain. In baking, this is important because when starch gelatinizes in the oven, the dough becomes much firmer, loses its flexibility, and from this point onwards it is unable to increase in volume. For this reason, anything that can delay the temperature of gelatinization can help increase the volume of bread. Gelatinization is also responsible for the need to make cuts in bread loaves. Without these cuts, the bread would break irregularly, but by making cuts, we ensure that the bread opens in a specific way. The reason for this tearing is that, once the starch has gelatinized, gases continue to be produced inside the pieces, or they tend to expand, exerting internal pressure on a mass that can no longer expand, eventually causing it to burst or open.

After gelatinization, if heating continues, the starch loses some thickening power, but in any case, it presents much greater thickening power than ungelatinized starch. After this process, when the starch cools, the molecules reorganize to form a structure that further hardens the pastes. This is the phenomenon known as retrogradation and is the cause, among other things, of the crumb’s texture. Thus, if you open freshly baked bread, you will find an excessively soft crumb, but as it cools, its texture changes to a firmer and more elastic one. This change is due to starch retrogradation. In starch, amylose is the part that tends to retrograde, while it is often said that amylopectin does not retrograde (as will be seen below, this is not entirely true). So, in the case of rice, those with a higher amylose content tend to be looser after cooking, as they retrograde more, and their texture, when cooled, is somewhat firmer and less sticky. In the case of wheat, there are usually no significant differences in the content of amylose and amylopectin between different varieties, so differences in crumb texture cannot be attributed to these changes. But if the starch has been degraded, to a greater extent by the action of enzymes, we may encounter crumbs that are too soft, as is the case with bread made from sprouted wheat.

As you know, bread tends to become harder and stale over time. While this phenomenon is partially caused by moisture transfer between the crumb, crust, and the exterior, it also occurs when bread is stored in airtight bags, reducing moisture transfer. Nowadays, we know that this hardening is caused by the retrogradation of starch, but it’s a slower and more gradual retrogradation, involving amilopectin as well. In fact, it’s known that this retrogradation is enhanced at lower temperatures, and pan breads become harder when stored in the fridge. Therefore, to reduce this hardening, one must act on starch and this retrogradation phenomenon, as will be discussed in posts addressing these topics.

Analysis Equipment

To analyse the behaviour of starch or substances containing starch, equipment is commonly used, which are essentially viscometers with temperature control. In these devices, a mixture of starch, or flour, and water is placed and subjected to gentle stirring. The measurement involves determining the resistance of the stirring device to move the mixture, as a measure of the paste’s viscosity. The standard analysis involves increasing the temperature to 95ºC, maintaining it at 95ºC for a period, and then cooling it to 50ºC. In the initial part of the curve, gelatinization is observed, including the temperature at which it occurs, and the maximum viscosity reached. Subsequently, a decrease in viscosity due to excessive heating is observed. Finally, retrogradation and the ultimate increase in viscosity are observed. The resulting graph is depicted in Figure 1.

Among these devices, the Brabender viscoamylograph and the RapidViscoAnalyser (RVA) from Perten are notable. The former is the older and was traditionally used in flour mills to study amylase activity, as higher amylase activity resulted in a lower viscosity peak. Currently, the RVA has replaced the viscoamylograph in many companies, although Brabender has introduced alternative equipment in recent years that functions similarly to the RVA. The advantages of the RVA include requiring a smaller sample size and performing the analysis more quickly. It’s also worth noting that the Chopin company offers a device called the mixolab, which functions as a combination of a farinograph and an amylograph. After kneading, it subjects the dough to heating and cooling, allowing for the observation of changes in dough rheology. In this case, the water content of the mixture is lower than in the previous equipment.

Figure 1: RVA analysis graph of wheat flour (grey line represents the temperature profile).