Equipment for Quality Control III: Fermentation

Rheofermentometer

We have previously discussed in the blog about quality control equipment that simulates the kneading process or dough handling. Today, we will talk about a device that simulates the fermentation process. I believe it is very useful for certain aspects and practically has no alternative. While it is true that the Brabender company has marketed equipment for studying fermentation, called the maturograph, this equipment is practically obsolete. On the contrary, the reofermentometer, developed by the Chopin company, has become the standard for studying fermentations.

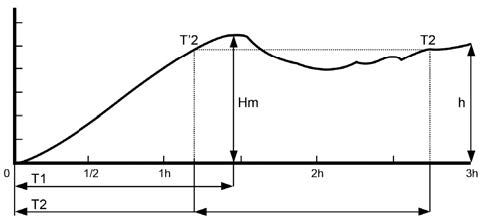

In appearance, it is a relatively simple device consisting of a container where the dough is placed, with temperature control capabilities. The equipment allows you to select a specific fermentation temperature to better simulate the desired process. This equipment can record the rise of the dough during fermentation, resulting in a curve representing the dough level. Ideally, you should observe a continuous rise in the dough, depending on the availability of sugars and the action of yeast. The equipment also offers the option to place weights on top of the dough. In fact, it is recommended to use all four weights, each weighing half a kilogram, totaling 2 kilograms. When the dough begins to weaken due to fermentation, these weights cause the gluten network structure to break, leading to a sudden drop in the dough. The breaking point varies depending on the quality of the gluten network, and the drop can be more or less pronounced. After the drop, the dough may recover to some extent. This allows us to study whether a dough can better or worse withstand excess fermentation.

Graphic with dough rise

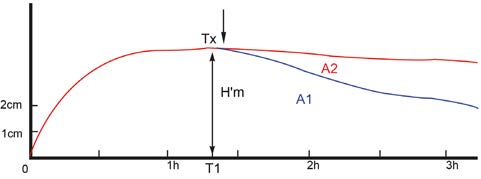

In addition to measuring the dough rise, the equipment can record gas production during fermentation and the gas retained by the dough. This generates a second graph composed of two curves. The first curve shows gas production, while the second records the gas retained by the dough. In the initial part of the curves, both coincide. However, when the dough breaks, they separate, with an upper part indicating gas production and a lower part indicating gas retention. The area between these two curves gives an idea of the gas escaping from the dough.

Graphic with gas production and gas retention

The protocol advises using a specific amount of dough, preparing it in a particular way using the kneader from the alveograph (remember that it is a Chopin device), and placing the weights on the dough. However, all of this can be adjusted. The important thing is to standardize the protocol to make it useful for your purposes. We have worked extensively with gluten-free doughs. These doughs are very weak and cannot withstand the weight of the weights during fermentation, so it is advisable to remove them. But in this case, with the recommended amount of dough in the protocol, the dough rises to its maximum point and remains there, depending on the formulation. Therefore, we have chosen to reduce the amount of dough used. Obviously, these doughs cannot be prepared in the alveograph kneader, so we use another system. If someone wants to work with wheat bread dough and does not have an alveograph, they can also use the kneader of a farinograph, a pilot plant kneader, or even doughs from a production line. In general, the use of weights is advisable since they allow us to obtain information about how the dough weakens, which typically happens as fermentation progresses. A lack of dough tolerance in bakery production lines can pose a problem, such as due to impacts between trays or other conditions that stress the dough pieces.

This equipment can provide a lot of information about various aspects and components of the dough. For example, if you maintain the same flour, you can study yeast behavior. You can see if fermentation starts earlier or later. This depends on the yeast’s adaptability to the environment and, in cases where no sugars have been added, the ease with which yeast metabolizes maltose. You can also determine if the yeast has a greater or lesser ability to produce carbon dioxide. By modifying dough characteristics, you can observe how yeast adapts to different conditions.

It can also be used to check flour quality because gas expansion and retention depend on protein quality and the quality of the gluten network formed. Lower-quality protein in flour will break down its structure earlier, allowing more gas to escape compared to higher-quality flour. Lower-quality flour is also less likely to recover well, resulting in weaker dough in the final stages of fermentation. Additionally, you can gain insights into amylase activity or the percentage of damaged starch, as maltose production, yeast activity, and gas production depend on these factors.

Perhaps the most notable use of this equipment, in my opinion, is for optimizing formulations and improvers (such as additives or enzymes). You can study how different ingredients influence this entire process, including additives that strengthen gluten, either in the early or late stages of fermentation, or various enzymes that can reinforce the gluten network, provide more extensibility (expansion capacity) to the dough, or assist in sugar formation.

In conclusion, it is a very interesting piece of equipment for R&D work and somewhat less suitable, in my opinion, as a routine analysis device. It’s worth noting that it is a time-consuming analysis, usually lasting 3 hours, although it can be shortened.

You can find more information on Chopin website